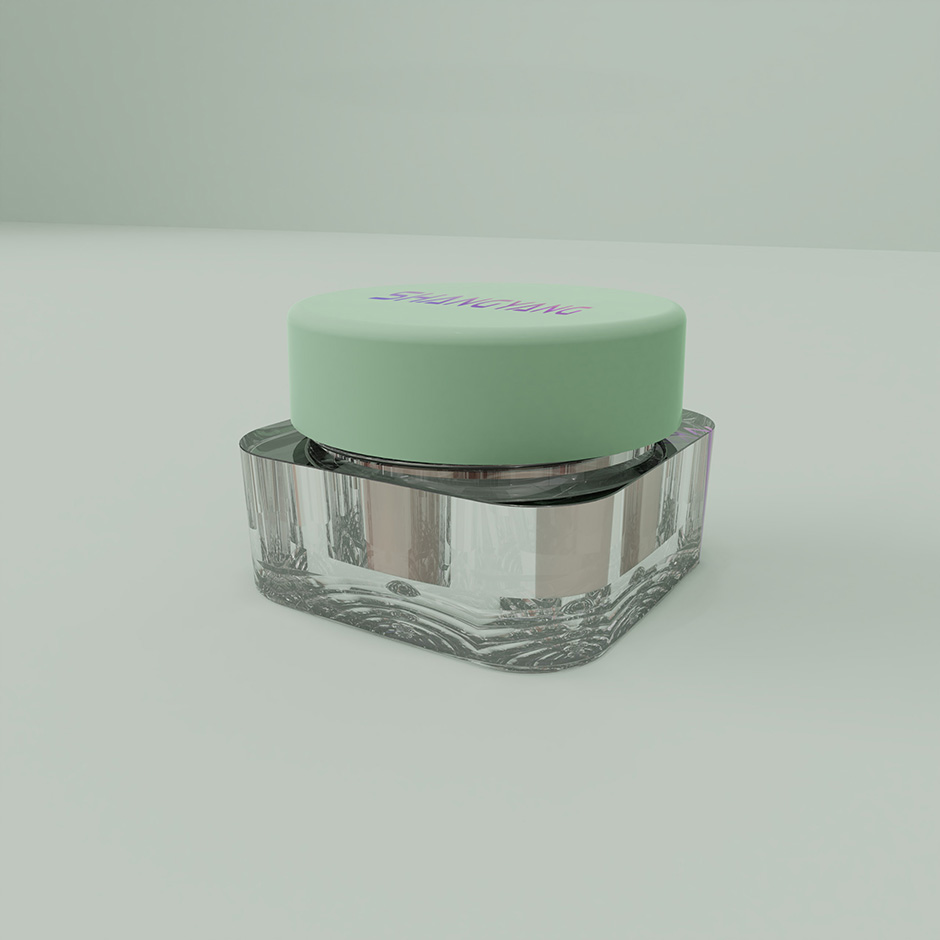

Eco Friendly Lipstick Packaging / SY-L001A

Packaging Description

The use of PCR packaging can also reduce the carbon footprint compared to traditional packaging materials. Producing virgin plastic requires a lot of energy and emits greenhouse gases during the manufacturing process. In contrast, PCR packaging uses less energy and reduces CO2 emissions. According to the Association of Plastic Recyclers, using one ton of PCR plastic in packaging production saves about 3.8 barrels of oil and reduces carbon dioxide emissions by about two tons.

Additionally, PCR packaging helps to raise awareness of the importance of recycling. By prominently displaying the "Made by PCR" label on cosmetic products, brands can educate consumers on the value of recycling and encourage them to properly dispose of packaging materials. This increased awareness has ripple effects, motivating individuals to adopt more sustainable behaviors and support recycling initiatives.

However, limitations and challenges associated with PCR packaging must be considered. One of the concerns is the quality and consistency of the PCR material. The recycling process can cause changes in the color, texture and performance of the final packaged product. Brands need to ensure that the quality of the PCR material meets their standards and does not compromise the integrity of the packaged product.

PCR Packaging Advantage

● Environmental Sustainability: PCR packaging reduces the need for new plastic production by utilizing post-consumer plastic waste. This helps to minimize waste going to landfills and reduces the consumption of virgin plastic, which is derived from fossil fuels.

● Reduced Carbon Footprint: Using PCR packaging reduces greenhouse gas emissions associated with traditional plastic production. PCR packaging requires less energy and resources for manufacturing compared to producing new plastic.

● Brand Image and Customer Appeal: Eco-conscious consumers are increasingly looking for sustainable products and packaging. By using PCR cosmetic packaging, brands can demonstrate their commitment to environmental responsibility, thereby attracting and retaining such customers.

● Cost Savings: Although PCR packaging may initially have a higher cost compared to traditional packaging options, it can result in long-term cost savings. Since PCR packaging reduces the reliance on virgin plastic, companies may benefit from cost stability and potentially lower input costs over time.

● Versatility: PCR packaging can be used for a wide range of cosmetic products, including bottles, jars, tubes, and caps. It offers the same functionality and aesthetics as traditional packaging options, allowing companies to maintain the desired look and feel of their products.

● Positive Consumer Perception: Using PCR packaging can enhance the perception of a brand as socially responsible and environmentally conscious. This can lead to increased customer loyalty and positive word-of-mouth recommendations.

Product Show